The Ultimate Guide to Silicone Sheets for Vacuum Presses

When it comes to vacuum presses, the importance of high-quality materials cannot be overstated. Among these essential materials, the silicone sheet for vacuum press stands out as a versatile and indispensable component. In this guide, we will delve into the characteristics, applications, and advantages of silicone sheets, alongside how they play a vital role in enhancing the performance of vacuum systems.

What is a Silicone Sheet for Vacuum Press?

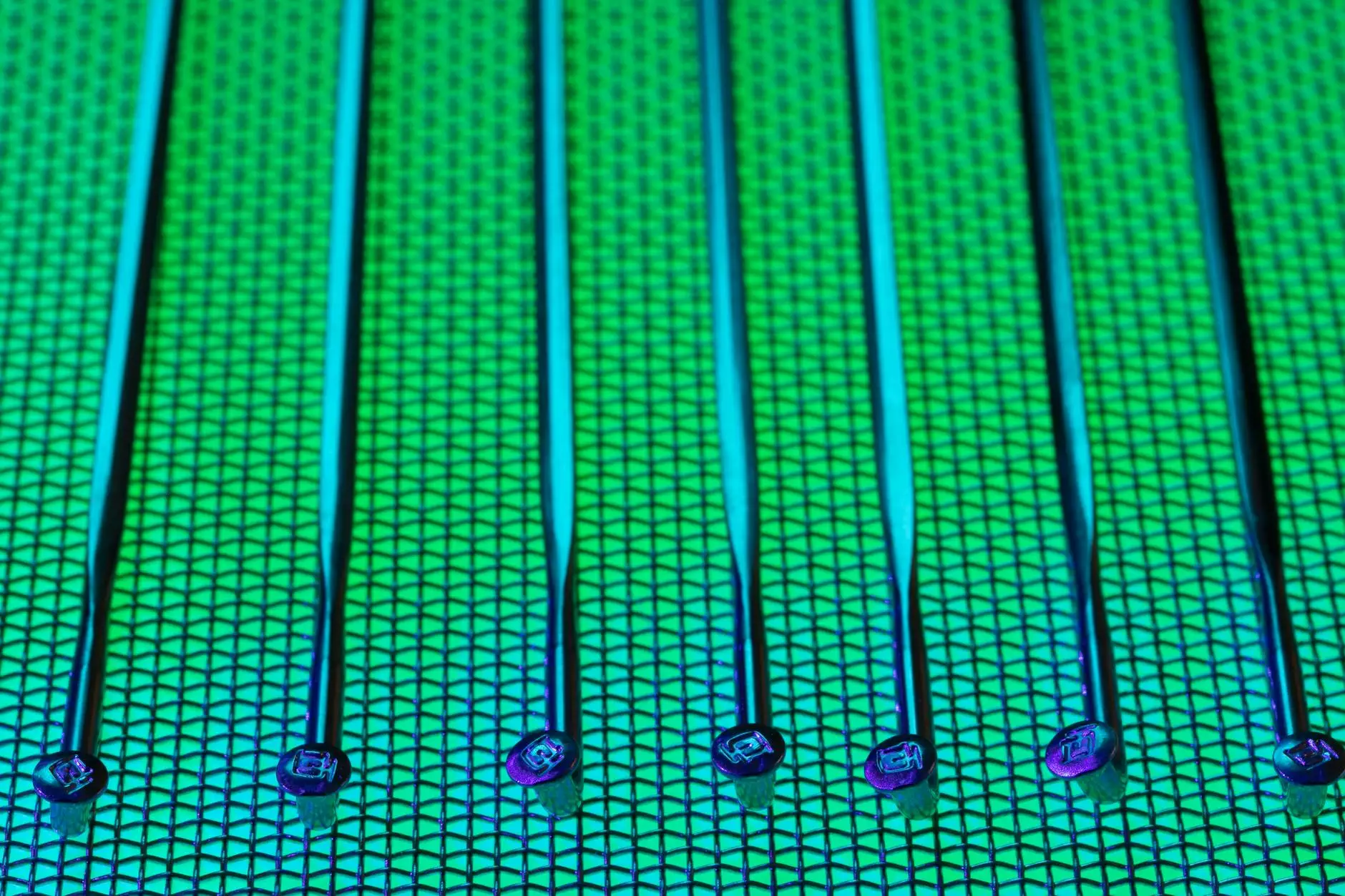

A silicone sheet for vacuum press is designed to create a reliable seal in various industrial applications. Composed of flexible, durable silicone rubber, these sheets are engineered to withstand high temperatures, offer excellent chemical resistance, and provide superior flexibility. Their flexibility is crucial when applied in vacuum presses, where the material needs to conform to the shapes and contours of the objects being pressed.

Key Properties of Silicone Sheets

- Temperature Resistance: Silicone sheets can endure extreme temperatures ranging from -60°C to 230°C (-76°F to 446°F), making them suitable for various applications, including heat pressing.

- Chemical Resistance: These sheets are resistant to many chemicals, oils, and solvents, which ensures their reliability in demanding environments.

- Durability: Silicone is known for its excellent durability and longevity, minimizing the need for frequent replacements.

- Flexibility: The inherent flexibility allows silicone sheets to adjust to different shapes and surfaces, ensuring a tight seal during the vacuum pressing process.

- Non-stick Surface: Silicone offers a non-stick surface that aids in easy release of the pressed materials.

Applications of Silicone Sheets in Vacuum Presses

Silicone sheets are utilized across a wide range of industries. Here are some prevalent applications:

1. Woodworking

In the woodworking industry, silicone sheets are essential for veneering and laminating operations. They provide a perfect seal, ensuring that the applied pressure is evenly distributed, resulting in flawless finishes.

2. Automotive Manufacturing

The automotive sector uses silicone sheets for molding composite materials, ensuring the parts are formed with precision and integrity.

3. Aerospace Industry

Silicone sheets are also prevalent in aerospace applications, where lightweight and durable materials are crucial. Their ability to withstand extreme temperatures and stresses makes them ideal for various components.

4. Electronics

In electronics manufacturing, silicone sheets help in encapsulating delicate components, providing them with the necessary protection against environmental factors.

5. Medical Devices

The medical industry benefits from silicone sheets, particularly in creating sealed environments for devices and ensuring sterility.

Advantages of Using Silicone Sheets in Vacuum Presses

There are myriad benefits associated with using a silicone sheet for vacuum press. Below are some of the key advantages:

1. Improved Efficiency

Silicone sheets enable faster processing times in vacuum presses due to their excellent heat transfer properties and flexibility. This improved efficiency can lead to increased productivity in manufacturing operations.

2. Enhanced Quality of Finished Products

Using silicone sheets results in better surface finishes. The non-stick nature helps in preventing material adherence, leading to cleaner and more precise final products.

3. Cost-Effectiveness

Despite an initial investment in high-quality silicone sheets, their durability and low maintenance requirements make them a cost-effective choice in the long run.

4. Versatility

Silicone sheets can be utilized in numerous applications across various industries, making them an all-in-one solution for many manufacturers.

5. Safety Compliance

Many silicone sheets are compliant with safety regulations, making them suitable for use in food and medical applications.

How to Choose the Right Silicone Sheet for Your Vacuum Press

Choosing the right silicone sheet can significantly impact your operation. Here are some crucial factors to consider:

1. Thickness

The thickness of the silicone sheet plays a critical role in the vacuum pressing process. Thicker sheets provide more durability and can handle greater pressure, while thinner sheets may offer more flexibility.

2. Temperature Rating

Select a silicone sheet with the appropriate temperature rating for your specific application. Different processes may require different thermal tolerances.

3. Chemical Resistance

Consider the materials you will be working with; ensure the silicone sheet can withstand any chemicals it may come into contact with during processing.

4. Size and Shape

Ensure that the silicone sheet fits your vacuum press properly. Custom sizes are often available through suppliers like vacuum-presses.com.

5. Surface Texture

Some applications may benefit from a textured surface for improved grip, while others may require a smooth finish for delicate operations.

Maintaining Your Silicone Sheets for Longevity

Proper maintenance of your silicone sheets is essential for longevity and performance. Here are some tips:

1. Regular Cleaning

After each use, ensure you clean the silicone sheet with mild soap and water. Avoid abrasive cleaners that can damage the surface.

2. Proper Storage

Store silicone sheets flat or rolled up in a cool, dry place. Prolonged exposure to sunlight or extreme temperatures can degrade the material.

3. Inspect for Damage

Regularly inspect your silicone sheets for signs of wear or damage. Replace any that are cracked or have lost their flexibility to ensure optimal performance.

Where to Buy Quality Silicone Sheets

When it comes to purchasing a silicone sheet for vacuum press, quality is paramount. Here are some reputable suppliers you should consider:

1. Vacuum-presses.com

Specializing in a variety of vacuum system parts including silicone sheets, Vacuum-presses.com offers an extensive range of products tailored to meet your business needs.

2. Local Industrial Suppliers

Check with local industrial suppliers who may offer custom silicone sheets and various options that suit your specific applications.

3. Online Marketplaces

Platforms like Amazon, eBay, and specialized industrial supply stores also have a variety of silicone sheets, but ensure you research the seller for quality assurance.

Conclusion

The utilization of a silicone sheet for vacuum press is essential for maximizing efficiency and quality in various manufacturing processes. Understanding their properties, advantages, and proper care will help you make the best choice for your specific applications. Remember to source your materials from reputable suppliers like vacuum-presses.com to ensure you're getting the best possible products that are tailored to your business needs.

With careful selection and maintenance, silicone sheets can provide outstanding performance, leading to superior results in your manufacturing processes. Whether you're involved in woodworking, automotive manufacturing, aerospace, or medical industries, incorporating high-quality silicone sheets into your vacuum pressing operations will undoubtedly elevate the quality of your products and enhance productivity.